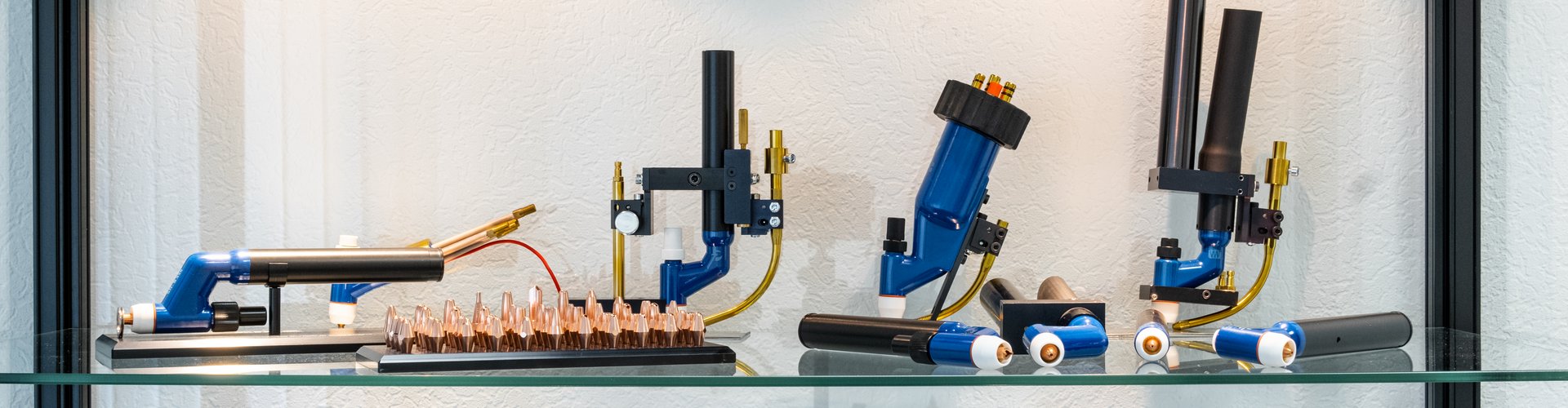

PHW 100P

Download:

Description

Small water-cooled and therefore high performance 100amps plasma powder welding torch (PTA/PPAW) for surfacing as well as joining. Ignition results without contacting with the workpiece by means of high-frequency and pilot arc.

Design

- Machine welding torch with round handle and indexed bore for robotic applications

- Hand welding torch with round handle

- Hand welding torch with ergonomic handle, switch and potentiometer for sensitive variation of the welding current or the powder quantity during the welding process

PTA Advantages

- Splash-free and smooth surfaces of seam

- Excellent gap bridging

- Minimal distortion because of a lower energy per unit length

- Two to five times more welding speed against TIG-welding

- No restriction when positioning the torch because there is no external cold wire supply

- High flexibility because you can join the most of weldable steels only with one type of powder

Highlights

- Simple assembly of the wear parts

- Long service life of torch and wear parts

- High flexibility, as all weldable steels can be joined with just one type of powder (similar to 1.4401)

- Low powder consumption

- Precise dosage Excellent gap bridging capability

Technical Data

| Electrode cooling: | indirect water-cooled |

| Nozzle cooling: | indirect water-cooled |

| Weldable thickness: | 0.05 up to 4 mm |

| Max. on - polarity: | 100 A |

| Duty cycle: | 100 % |

| Powder particle size: | -200 +60 µm |

| Powder deposition rate: | 20 g/min. |

| Plasma gas: | Argon |

| Shield gas: | Argon, Argon/Hydrogen |

| Application: | PTA hardfacing PTA surfacing PTA joining Extruding machine screws Valves for motorcar, marine etc a.s.o. |

![[PDF] Data sheet PHW 100P](/fileadmin/_processed_/6/a/csm_Prospekt-PHW100P_436b9b5ffe.png)