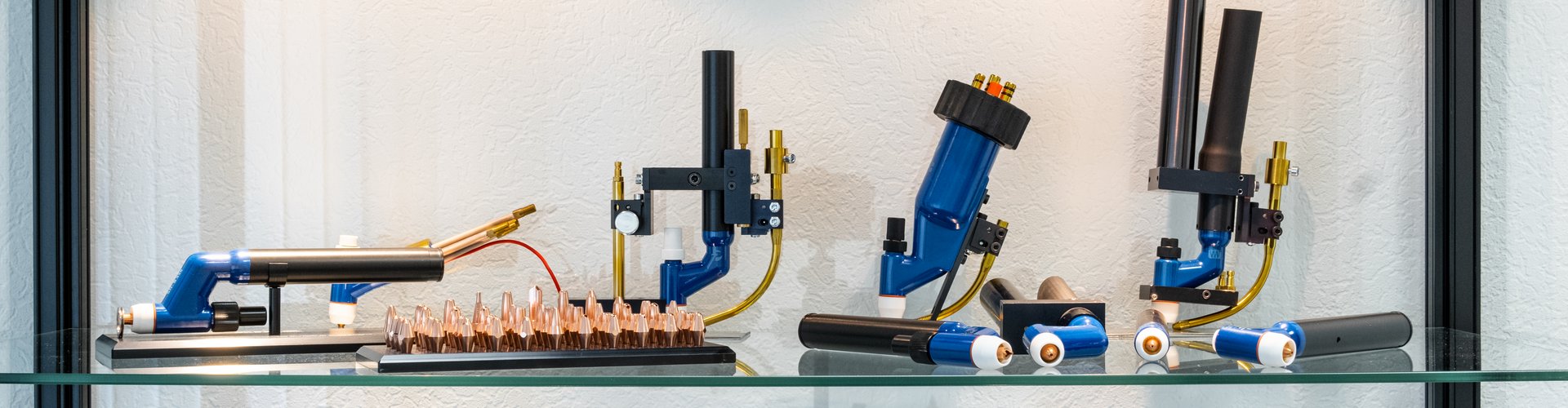

AMW 250

Description

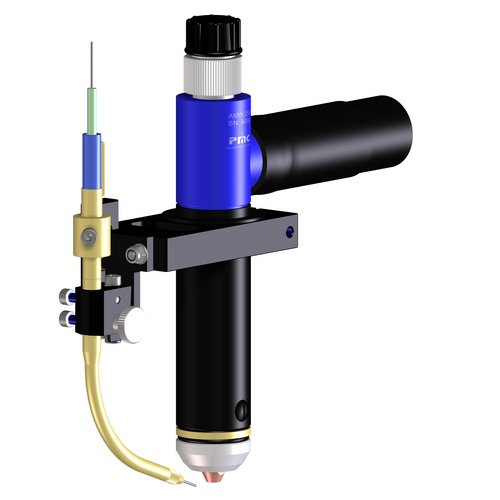

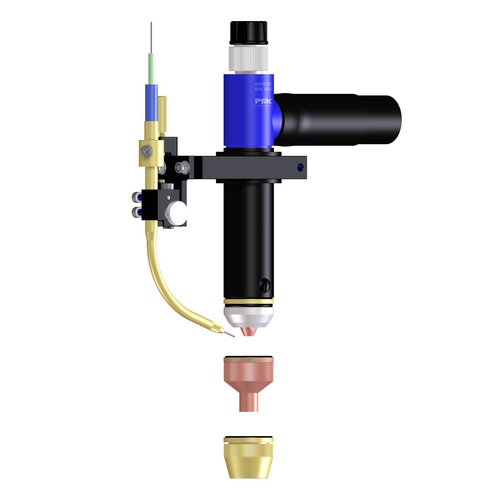

Slim, watercooled 250 A two-way torch suitable for mechanized TIG-welding with pilot arc as well as for mechanized plasma welding.

Laminar shield gas flow by various special designed shield gas nozzles for all kinds of application.

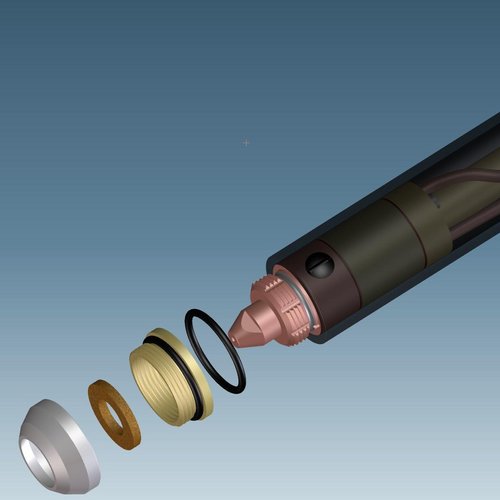

The AMW 250 is equipped with a closed water cooling system, which means that there is no loss of water when replacing the wearing parts. Because of the special designed electrode fixing unit you are able to modify the electrode distance as well as the arc characteristic during the welding process.

Accessories

- Various Gas Nozzles fitted for most of welding application

- Cold Wire Supply for exact guiding of the wire in the arc

- Transversal Wire Adjustment for easy adjustment of the wire to the middle of the seam

- Special coolant to prevent electrolytic corrosion in the welding system. Saves the pump, the hose package as well as the cooler

Highlights

- Electrode adjustment possible during welding operation

- Simple assembly of wear parts

- Long service life of torch and wear parts

Technical Data

Max. current-carrying capacity Plasma:

| Electrode cooling: | indirect water-cooled |

| Nozzle cooling: | indirect water-cooled |

| Weldable material thickness: | 2 up to 6 mm |

| Max. current-carrying capacity TIG: | 250 A |

| Max. current-carrying capacity Plasma: | 200 A |

| Duty cycle: | 100 % |

| Plasma gas: | Argon |

| Shield gas: | Argon, Argon/Hydrogen, Argon/Helium |

| Application: | Reactor engeneering Pipeline construction Power plant construction Instrument-making Longitudinal and circumferential Seams Pipeflange joints Hardening Torch a.s.o. |

![[PDF] Data sheet AMW 250](/fileadmin/_processed_/e/e/csm_Prospekt-AMW250_a4b6281ef6.png)